#ACI CLASS B LAP SPLICE FULL#

Users should refer to the original published version of the material for the full abstract. No warranty is given about the accuracy of the copy. However, users may print, download, or email articles for individual use.

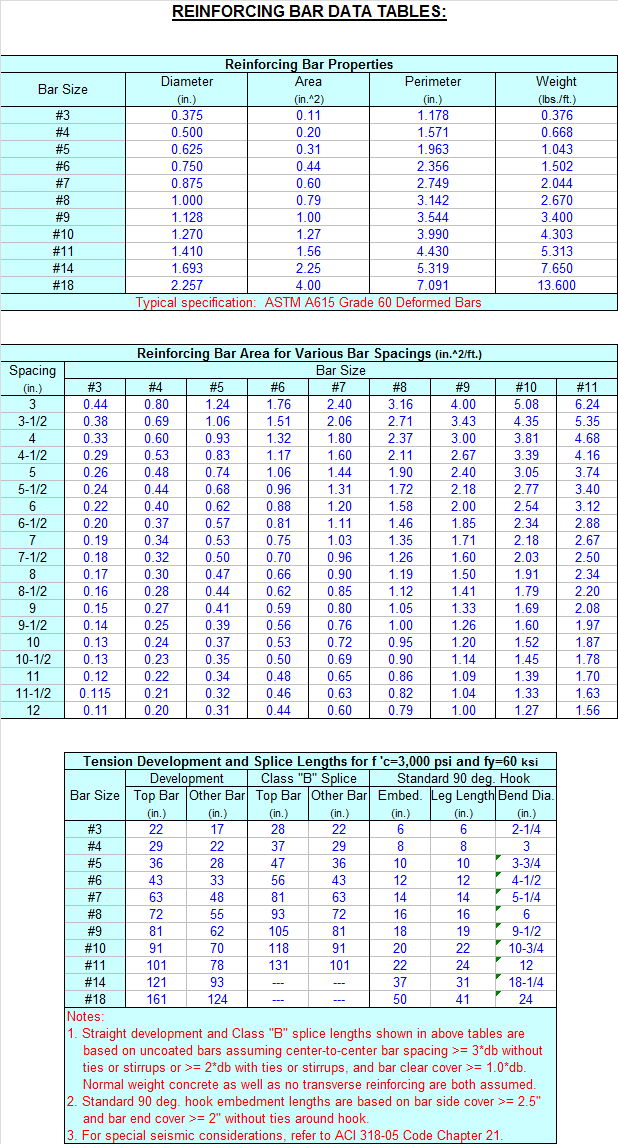

For D22 and D32 bars, the use of either transverse reinforcement or thick concrete cover was recommended to develop the specified yield strength of 600 MPa (87 ksi). Mechanical Splice Requirement ACI 318 Chapters 18 and 25 state the requirements for mechanical splices. The results showed that the reinforcing bar splices gave a satisfactory performance for all D13 (diameter = 13 mm ) bar splices. The note should simply say: Provide the following lap lengths for reinforcing steel in concrete unless otherwise noted. The average bar stresses resulting from this test were compared with the predictions by the ACI 318 provisions. The contents of the schedule of laps is much more important then the note that refers to the schedule. Most of the specimens were designed to satisfy the Class B splice length specified by ACI 318. I see a lot of the newer material (specifically the 2002 CRSI Design Handbook) uses something called 'Lap Classes' types A and B. Ive always used the standard ACI 318 equations for determining tension and compression lap splices. Concrete strengths ranged from 24.7 to 55.3 MPa (3582 to 8021 psi). Reinforcing Splice 'Lap Class' Explanation. The test parameters were the reinforcing bar diameter, concrete cover thickness, concrete strength, and stirrup spacing. Twelve simply supported beams and slabs with reinforcing bar splices were tested under monotonic loading. Abstract: An experimental study was performed to evaluate the applicability of ACI 318 to the Class B splice of 600 MPa (87 ksi) reinforcing bars.

#ACI CLASS B LAP SPLICE CODE#

Please!! I need clarifications if this statements of the ACI code must be interpreted literally. Do we really need to interpret this Literally?I mean do we really need to splice it exactly over the support when needed? technically this produces a lot of waste if we should strictly follow this. The ACI code clearly states that at non-perimeter at least two bars or at least 1/4 of Area of rebars must be continuous or splice(class B tension lap splice) over the support. Splice types are described in ACI Table 10.7.5.2.2. I wonder what section of the aci code allows this? ACI Table 25.5.2.1 gives the required length of a lap splice as a. Minimum lap-splice lengths of rebars in compression Ls vary with nominal bar diameter db and yield strength Æ’y of the bars. but I do not know in what section of the code allows it. For Class A splices, For bundled bars in compression, the development length of each bar within the bundle should be increased by 20 for a three-bar bundle and 33 for a four-bar bundle. Connections can be made in seconds in virtually any weather conditions, and the finished connection. Designed to simplify installation, our mechanical lap splicing systems require minimal training and are field-proven for their strength and cost-effectiveness. If I made 2 bottom bars continuous and I had to splice near the column,do I need to stagger the lap splicing? I have seen a link that it is allowed not to stagger it. Join small-diameter reinforcing steel bars in seconds with nVent LENTON Quick Wedge.

My question is : if I have 3 top bars and the two top bars ( at the sides ) are made continuous, do we need to stagger the splices? if so, what provision in the ACI code allows this? and do we really need to splice (class B tension lap splice) =it exactly at mid-span? Under gravity loads or in most cases the top bars at mid span and the bottom bars near the supports (in a doubly reinforced beams ) receives compressive stresses. The ACI code gave a provision on structural integrity to perimeter beams is to splice continuous top bars at mid span and splice continuous bottom bars at or near supports.

0 kommentar(er)

0 kommentar(er)